About Our Candles

Candles were never just about light but about spirit too; handmade candles just contain more of it.

Beeswax is a beautiful medium because of its simplistic and natural purity. There is nothing quite like the subtle, sweet aroma of honey filling my studio space; beeswax, made by honey bees, needs only to be shaped into a candle which provides hours of golden light creating the perfect ambiance.

It all begins at the hive. I procure Canadian cappings wax from beekeepers who haven't scorched or overheated the wax when separating out the honey. Then, in order to maintain the integrity of the wax, I filter it down to one micron through a gentle and thorough cleaning process.

I've always been passionate about quality and I endeavour to source only the best cappings wax from local Canadian beekeepers. I am ever vigilant how the wax has been handled from the hive through to production, filtering it down to micron purity. Each and every candle is poured by hand and fitted with an appropriate sized 100% cotton wick.

When you purchase a Your Time™ candle you can be confident you’ve sourced a product where every effort was made to produce the best quality beeswax candle.

Carol Kubassek, Master Chandler at Your Time Boutique

What's different about candles made from beeswax?

It is common knowledge that candles can be made from a variety of waxes. Perhaps the most common are paraffin and vegetable based waxes. Beeswax is one of the purest and most natural waxes. It is one of the only waxes that is being used primarily in its raw form with only filtering for processing. Unlike other inferior waxes, beeswax is all natural. Beeswax candles are intrinsic to a healthy home and lifestyle. When burning, beeswax candles give off a beautiful warm golden glow.

![]() What are the benefits of beeswax candles over candles made from gel, paraffin, soy or other waxes?

What are the benefits of beeswax candles over candles made from gel, paraffin, soy or other waxes?

Beeswax is wax that comes complete from nature. Unlike paraffin, soy or other types of wax, there is no man-made processing or chemicals used to produce it into a wax.

Beeswax candles are the perfect alternative especially for people who have asthma, allergies or headaches made worse by paraffin or any artificially scented candles.

Have you ever been to a dinner party, and the hosts have done their best to create a beautiful ambiance with burning candles set out everywhere? (Only, they've lit paraffin, or worse, scented paraffin candles.) The fine china has been laid out, and the lights dimmed. The rooms begin to fill with silent vapours from the burning paraffin candles. As the evening wears on, you start feeling foggy-brained, your eyes start watering, and your sinuses get stuffed up. You're likely experiencing a reaction to the toxic fumes coming off the candles..

Paraffin is a petroleum by-product. There is a danger lurking behind this seemingly innocuous product. It is a known fact, and studies have shown that paraffin candles, especially scented ones, can release far more soot and toxic emissions into the air when burning compared to any other candle. Many people experience headaches and dizziness from burning paraffin candles not to mention potential damage to home interiors and contents from candle soot deposits on everything.

With beeswax candles, you don't get these same side effects. As the candles burn away there is a subtle honey aroma that you might notice. And in contrast to what you may have experienced with paraffin candles, the air actually feels cleaner when beeswax candles are burning. This clean-air effect is a result of the higher amount of negative ions beeswax put out. Plus, they don't produce any carcinogenic petrochemical pollutants.

Of course, anything that burns produces some sort of toxins and burning beeswax candles in quantity simultaneously, will also produce soot in areas of the home. With their warm golden glow, over all, we believe pure beeswax candles, made from properly cleaned cappings wax and 100% cotton wicking, are healthier, economical, and most pleasurable to burn.

Is it true that beeswax candles purify the air when burning?

All burning candles produce negative ions. Beeswax candles burn hotter than candles made from other waxes which means they put out more "negative ions" than candles made from other waxes. The negative ions circulate in the room, attracting and neutralizing pollutants, (positive ions). Negative ions are nature's air purifiers, cleaning the air of dust, mould, bacteria, viruses, and other pollutants.

A Japanese laboratory tested the number of negative ions given off by beeswax candles versus "regular" paraffin candles. According to the lab measurements, paraffin candles produced an average of 72,972 negative ion particles per cc of air. Beeswax candles, on the other hand, emitted an average of 101,276 negative ion particles per cc of air. At their peak, the paraffin candles released 79,790 particles per cc, and beeswax produced 126,800 particles per cc.

*For the technically inclined: the test was performed using the KST-900 made by Kobe Electric Wave Company. The room air was 24.3 degrees Celsius, the room air moisture content was 41%, and the background negative ion count was 89 per cc. (Beeswax and Paraffin Candle Test - Japan)

So according to this study, burning beeswax candles releases a much higher amount of negative ions than candles made from other waxes.

What we have found is that after burning several beeswax candles in the same room for a few hours the air has a charged feeling which can be likened to the atmosphere after a Spring rain; odours seem to dissipate and the air feels "cleaner".

Where do you source your beeswax from?

Our beeswax hails from small apiaries across Canada: Ontario, Manitoba, Quebec, Alberta, New Brunswick. We source our wax from beekeepers who employ more natural methods of beekeeping in order to keep their bees as healthy as possible. These beekeepers use little to no toxic chemicals in the hive, and they are careful not to scorch the wax, or heat it for extended periods of time, when separating out the honey. Starting at the hive, careful handling of the wax throughout the entire creative process is paramount in yielding excellent quality candles.

Quality: are beeswax candles all the same?

The way beeswax is filtered is a critical step in producing top quality, clean burning candles. During the extraction of the honey, the beekeeper removes the "cappings" wax from the comb recovering as much honey as possible. We procure the cappings wax from the beekeeper and proceed to render it carefully. This entails removing any left over honey and hive debris. It is at this critical stage of the process that the quality of the cappings can be determined.

Some chandlers claim to triple filter their beeswax. They pour the melted wax through three layers of "cloth" or nylon pantyhose. Filtering the wax this way is highly ineffective as the pores in the fabrics are too large to filter out the microscopic suspended particles that would clog the 100% cotton wicking.

The most effective ways of filtering beeswax are by using an uncomplicated, gentle method of gravity and patience; then finally filtering the wax through 1 micron filters or through a pressurized 5 micron screen system.

The beeswax arrives in our shop in it’s raw form as cappings or, it comes as partially cleaned crude beeswax. We then proceed to purify it further through this gentle settling and one-micron filtration process. This process guarantees a high-quality raw material which we then use to make our candles.

Why are your beeswax candles such a bright yellow colour?

Our candles are made from pure, high quality, carefully cleaned, yellow cappings wax from bees. The colour of our candles is completely natural and usually a blend of two or more different colours of beeswax. The beeswax we use to make our candles is sourced from different regions in Canada. The colour of the wax will even vary from field to field. We usually blend the different colours of beeswax to create a luscious yellow colour for our candles.

Some of our beeswax hails from Quebec and New Brunswick hives situated near blueberry fields; our Ontario wax, may come from hives situated near goldenrod, wildflower and dandelion meadows. Our Alberta beeswax is a blend from hives near alfalfa and clover fields. The blueberry and goldenrod fields yield a rich, deep almost pumpkin-coloured beeswax, and the clover, a soft, buttery yellow. By combining the different colours we get a vibrant, juicy yellow shade.

That said, the region or location the beeswax came from is not the only factor will determine the quality or colour of the candles. To help you understand our process better, read on.

Inside the hive the bees use the comb to store honey and raise their brood. Once the comb is filled with honey, the bees seal the honey with a thin layer of wax known as the "cappings". Because of this activity there are different grades and colours of beeswax available: cappings, old honeycomb and brood comb wax.

When the bees first secrete the wax from glands on their abdomen the wax is white. This layer of wax eventually yellows from the honey, pollen, etc. It is this thin layer of "cappings" wax we cherish to make our candles.

Honeycomb and brood comb are usually a dark brown or green-brown colour. (These kinds of wax are not suitable for our candles.)

How the cappings wax is cleaned and filtered, from start to finish, makes all the difference in colour and aroma of the end product. If heated too high and also, if heated for extended periods of time, the honey in the wax will darken and the dirt will bond to the wax. The resulting scorched wax will be poor quality and cannot be used to produce quality candles.

By using careful cleaning protocols, the full bodied aroma, the natural yellow colour and overall integrity of the beeswax is preserved.

When we make our candles we work in small batches. This way we are only heating the beeswax for a minimal amount of time.

Beware! Not all Beeswax Candles are made with 100% pure beeswax

Not all beeswax chandlers make their candles using quality cappings wax. In some cases, beeswax is cut with other vegetable waxes and the candles are still sold as "beeswax candles".

To make the expensive cappings wax "go further" some candlemakers will actually combine the lower grade wax like old honeycomb and brood comb, to make their candles. That explains why beeswax candles vary so much in colour. As for those ‘butterscotch coloured’ and ‘brown’ beeswax candles, well, quite simply, those are just made from scorched beeswax or wax that's been exposed to heat for too long; this includes those extra dark brown beeswax candles which are masqueraded as "buckwheat" beeswax or beeswax coming from "exotic" nectars - this dark brown wax is most likely a result of extra scorched beeswax.

Once upon a time in our candle lab, we had a small amount of wax overheat. The the wax turned from bright yellow to a dull brown. One day we purchased some candles made by a competitor and only when we compared the colours did we discover those candles were the same hue as our scorched beeswax.

What makes a successful beeswax candle?

Not only the quality of beeswax, but also the type and size of the wicking used, how the candle is made and how the candle is cared for while it’s burning, will determine how successful a candle will burn.

When a candle burns, it is vaporized wax that is actually burning. The solid wax first has to be melted by the heat of the flame and through the capillarity action of the wicking, be drawn up to the combustion zone where the wax is vaporized and then burned.

Presuming the candle is made with clean cappings wax, along with a properly matched, 100% pure cotton wicking, the wax will be consumed efficiently. As long as there is no draft in the room while the candle burns, the candle won't require a lot of maintenance, rather, it will produce a bright, clear, steady flame and beautiful illumination.

Given the fact that our beeswax candles are made with wax that is filtered down to one micron or less, we are able to use 100% cotton wicks exclusively in all styles of our candles. Cotton wicking isn’t tolerant of dirt in the wax. By cleaning the wax as well as we do it lends to a superior burning candle. Our candles have been tested extensively making sure we’ve married the perfect wick to each different candle size.

There are chandlers who use lower grades of beeswax to make their candles. This wax isn’t filtered adequately in order for the candle to burn successfully with a cotton wick. In this case a jute, hemp, or hand-rolled coarse "natural fibre" wicking is sometimes used as this type of wick compensates for the poor quality wax and is more tolerant of dirt in the wax. Moreover, not only are these types of twine wicking decidedly irregular, they also contain oils within the fibres which, when burning, produce somewhat of a pungent odour, and unlike the 100% cotton wicking, the liquid wax around this wicking will darken as the candle burns. Also due to the unevenness in the weave of these natural fibre wicks, at times the candle flame will reach a spot where the wick is clogged and refuses to burn any further. Undeniably, these kinds of candles are not the most successful burning candles.

Proper care of your beeswax candle as you're burning it, is also part of making it a success. See our "Candle Care" page for tips on how to care for your candles.

How does a candle flame work?

The English scientist Michael Faraday once said, "All the natural forces encountered in space can be found in the chemical history of a candle".

Definitely intriguing, here, we examine the (beeswax) candle flame in a scientific way.

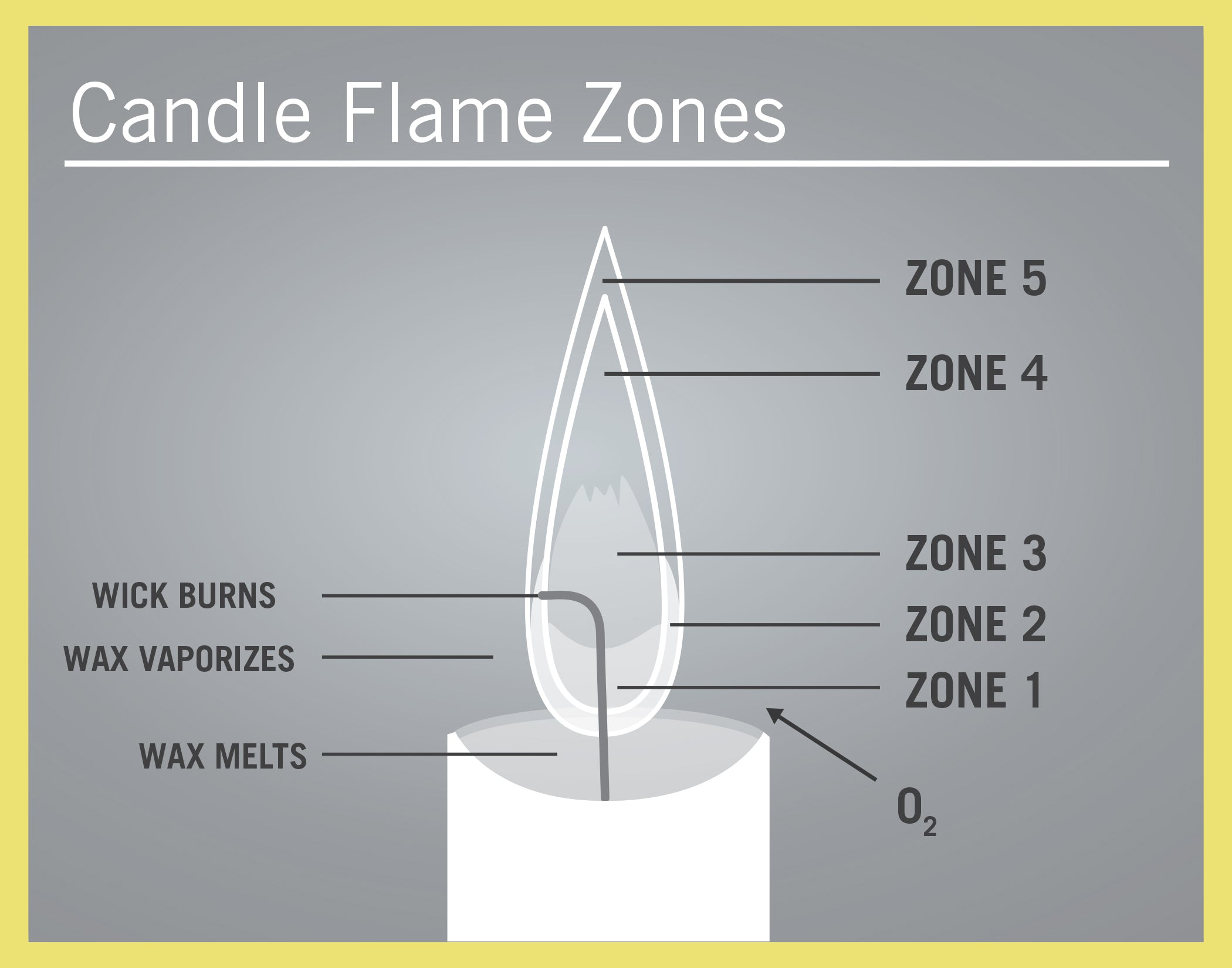

Zone 1 (Non-Luminous Zone, approx. 600°C) When we light the wick of a candle, fuel on the wick evaporates. There is insufficient oxygen for the fuel to burn.

Zone 2 (Blue Zone, approx. 800°C) There is a surplus of oxygen and the flame burns clean and blue. The heat from this zone melts the nearby wax to allow for wicking. The liquid wax then rises up along the wick by means of the capillary action.

Zone 3 (Dark Zone, approx. 1,000°C) As the liquid wax rises, it is exposed to higher temperatures causing it to vaporize when it reaches the end of the wick. Due to the shortage of oxygen, pyrolysis (cracking) of the fuel begins, creating minute carbon particles.

Zone 4 (Luminous Zone, approx. 1,200°C) As the carbon particles rise through the flame the heat increases causing the carbon to emit light and burn. When they reach this bright yellow area there is still insufficient oxygen for complete burning so pyrolysis continues and larger carbon particles are produced.

Zone 5 (Veil, approx. 1,400°C) There is oxygen surplus in this non-luminous zone and when the burning carbon particles reach the edge of the flame the available oxygen causes the heat to increase, allowing the carbon particles to burn faster and more completely at the boundary between Zone 4 and Zone 5. The square braid wicking we use in our candles, is designed to curl which broadens the flame and exposes the tip of the wicking to this hottest part of the flame. This allows the wicking to burn away cleanly.

The convection current created by the rising of the hot fuel draws more oxygen into the flame. If a draft lowers the temperature, the flame will be affected. The resulting flame, not allowing the carbon particles to be burned away cleanly, will produce soot particles which end up being collected on the tip of the wicking and/or distributed into the air.